As years passed working with Shetland wool I naturally gained hands on experience as well as instruction from more experienced individuals be it crofters, farmers, or wool merchants.

In my previous blog on Shetland sheep I mention the Shirreff report on Shetland sheep and wool. We appreciate nothing much has changed up to the present day in that there are still two distinct types of Shetland sheep. “A ‘kindly’ fine wool sheep, the other of mixed quality with wool that is partially coarse”. It is very obvious that these two distinct types of Shetland sheep interbreed and so you have a mixture of wool qualities.

The fine fleece has an even and well defined crimp, with an even and uniform length of staple, it should also have sufficient tensile strength of staple, and the fleece should have a soft handle. Over the years I have heard two explanations of the required length of “Britch” on a fine Shetland fleece. The Britch should be covered in the palm of your hand with no coarser wool staple visible. The other theory is that the Shetland sheep needs a heavier “Britch” or hips to protect it whilst resting on the heather.

The finest Shetland wool cannot match the micron count of the Australasian breeds, such as the Merino, on fleece average the finest Shetland comes in around 24.5 microns while the Merino can be in the teens. The Shetland fleece soft springy handle is much more superior to that of the Merino which has a dense feel to it.

The other coarser type fleece has a much longer staple, with little in the way of crimp and consists of two parts, “and not two separate coats”, a stronger coarser fibre in order to protect from the inclement weather and the under part of the staple for warmth. Some older crofters would tell me that in a really hard frosty winter the sheep would produce less outer wool but more inner wool for warmth.

In 1978 came the introduction of the wool grading scheme, a much fairer system to all concerned, producer, merchant and end user. Five grades of white wool, and two grades of coloured, was introduced which applied a standardised grading system that the purchaser of the wool could work his margins from. We still stick quite rigidly to this method of grading today. As the main buyer of the local wool clip, over 80%, according to local trading standards, we have a responsibility in our handling of the clip for all parties involved in the wool process. The only down side in my opinion in the system is that with two separate companies in the islands grading the wool if there is not combined continuity of standardised grading there is an in-balance of end results, which causes confusion.

The grading is determined by the wool quality, if there are more coarser fibres present the lower the grade. Presentation of the fleece that is rolling it from the Britch to the neck with the wool staple outward is how it should be done. In most Shetland fleece the finer wools are more prevalent around the neck and shoulder areas. A perfect example of fleece presentation I was personally involved with took place in the first and second year of the scheme. A crofter approached me at the end of the first grading year and stated he was disappointed with his wool returns having only a small amount of grade one. I took a Shetland fleece on my sorting table and proceeded to roll the fleece from the Britch to the neck folding in the coarser staple out of site, explained he had not rolled his clip and so had not shown of the best of his wool. The end of the next wool season my boss asked me to explain why the same crofter’s wool clip was mostly grade one!

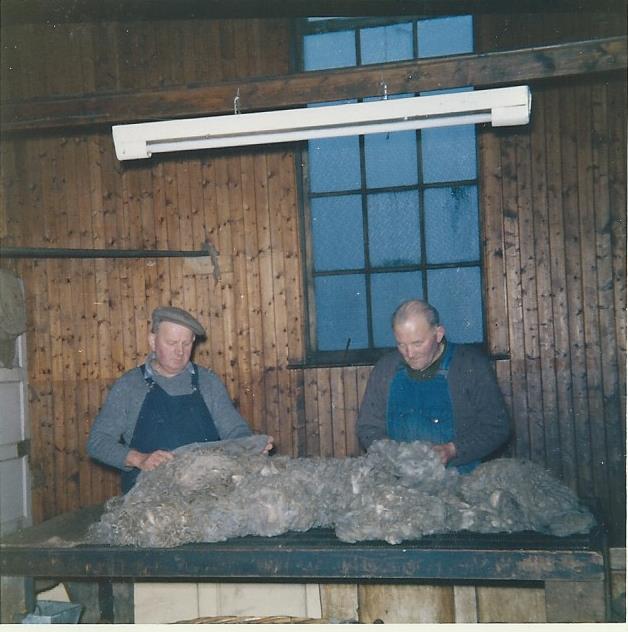

Because of this mixture of wool qualities occuring in a fleece it is very necessary that after grading wool sorting has to be done and the only means to separate the different types is by hand. There are various types of qualities sorted depending on the finished product. The stronger guard hair wool staple (lock) which can form part of the fleece, is sorted away leaving the finer fibre which will be used in high quality knitting yarns such as Shetland Supreme lace. This is a very time consuming and skilled job which is very necessary in order to produce a high end quality product. Sorting is done after the wool is graded and done in the quieter winter months, very similar to the method introduced by “Sheepie” s explained in my previous blog.

The lower grades of wool and the coloured wools were very difficult to find a home for up until the mid-1990s, I will explain the change in later blogs.

Definition of Terms Used in Grading Specifications

Degree of fineness

The diameter of the wool fibre influences to a large extent the use to which the wool can be put and also the length of yarn that can be spun from a given weight of wool. Users and manufacturers normally use a series of quality numbers to indicate fibre diameter. These numbers, in ascending order of fineness are, are 28s ( the thickest, coarser fibres ),

32s, 36s, 40s, 44s, 46s, 48s, 50s, 56s, 58s, 60s, 64s, 66s, 70s, 90s, 100s (the very thinnest, finest fibres). Most British wools are within the range 28s to 58s. Shetland finest 58s – 60s. Quality numbers are not based on any particular unit of measurement; they are standards handed down from generation to generation of wool men and can be learned only by practical experience and handling of wools.

Length of Staple

This is the measurement of the unstretched staple from tip to base. The figures quoted are standard for each grade.

Handle of Wool

The softness or harshness of the wool when handled.

Degree of Lustre

This refers to the amount of gloss or sheen visible on the fibres. Degree of lustre varies greatly between types. A bright lustre is an asset for certain manufacturing processes.

Colour

The nearness of the wool to white ( or black in the case of black fleeces).

Strength

The ability of the staple to resist breakage during manufacture. The word “sound” is used to describe wool of satisfactory strength rather than “strong” which, in wool terminology, refers to thick or coarse fibres. The opposite of sound wool is “tender” wool. Tender wools may have a break in all the fibres at one point in the staple as a result of illness or drought or in the case of the Shetland a very hard frosty spring.

Other Terms Used Include

The presence of grey or black fibres in a fleece restricts its dyeing range to the darker shades. This fault occurs in many of the white – woolled breeds.

Dear Ollie,

One must really have to get trained hands and eyes for this job ! It’s a gift ! Very interesting read !

LikeLike

Another great post, I am really enjoying the detail you are including about the process and the importance of these stages in the preparation of the final products.

LikeLike

That fine wool sheep looks like a proper ‘lady’ with her hair done just so! Good explanations for a very subjective/objective job. thank you again.

LikeLike